Eon Instrumentation, Inc. is a veteran owned electronic systems design, development, and manufacturing company with two well equipped facilities in Southern California. The Van Nuys facility is the corporate headquarters with program, engineering, manufacturing and support organizations serving all of Eon’s product lines. The Oceanside facility provides staff responsible for System and Qual/ESS testing of all Eon product lines as well as an engineering center of excellence for Interference Blankers and Rugged Power Supplies. Eon has a 57-year history of delivering quality products, systems, and services for the aerospace and defense industry. Eon is a certified FAA repair facility #EOIR152X. Eon has been an ISO9001:2015 and AS9100D supplier since 2012.

Our current product offerings include hardware and software for:

New Product Development

Main Products tab provides a complete list of Eon’s product portfolio with summaries and attached data sheets.

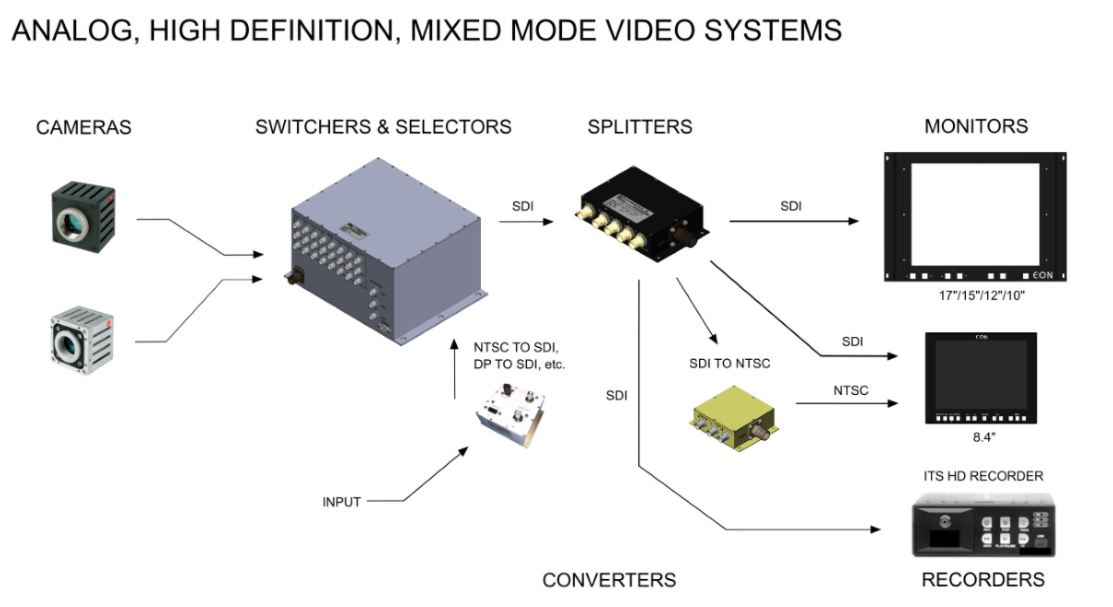

Our products are delivered as individual LRU’s to integrate with other system architectures or Eon can provide “end to end” system solutions. An example is an HD/SDI configuration of cameras, monitors, and recorders integrated through a video splitter matrix appropriate for an airborne or ground platform.

The key ingredient of Eon is a mix of carefully selected staff of technical, manufacturing and business development specialists, adept at working as a team. They possess the necessary skills and processes to engineer, manufacture and support what customers need, not just generic off-the-shelf LRU’s. Eon partners with our customers to deliver end results. Eon will often invest its internal R&D funds to create or tailor existing hardware and software to create unique products or systems. Eon welcomes all customer inquiries, and routinely develops six+ new or modified products per year.

Example New Product Development: NASA required a dual redundant 6G DisplayPort input, multi HD SDI and NTSC port output unit for the NASA X-59 supersonic aircraft. Eon was selected to design this unit because of it’s expertise in HD processing and video format conversion.

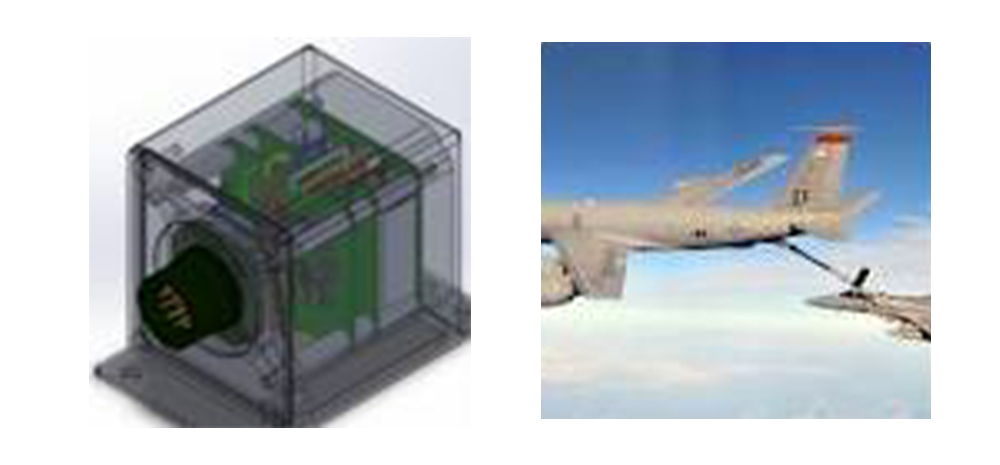

Example New Product Development: A Refueler interface was required for a new fighter aircraft. The unit is required to provide audio communication and digital boom control between the Refueler and the fighter. Eon was selected to design and manufacture this unit because of its expertise in airborne audio and digital control systems.

Example Product Reverse Engineering Development: A PAM telemetry low pass filter unit was used in a 1980’s era Air to Ground missile. The USG decided to renew production of the missile but all design documentation had been lost. Using the acceptance test document and some original prototype units Eon was able to reverse engineer the unit including recreating all the inductors, obsolete parts, pcbs, chassis, connectors etc. The unit is now in production.

Existing Product Modification/Upgrade

All of Eon’s products are designed using modular circuit, software, connector and chassis components. Eon engineers also use the most current design, simulation and manufacturing tools that integrate the complete start to finish process. From this basis Eon can easily modify an existing production product to create a new model/part number product.

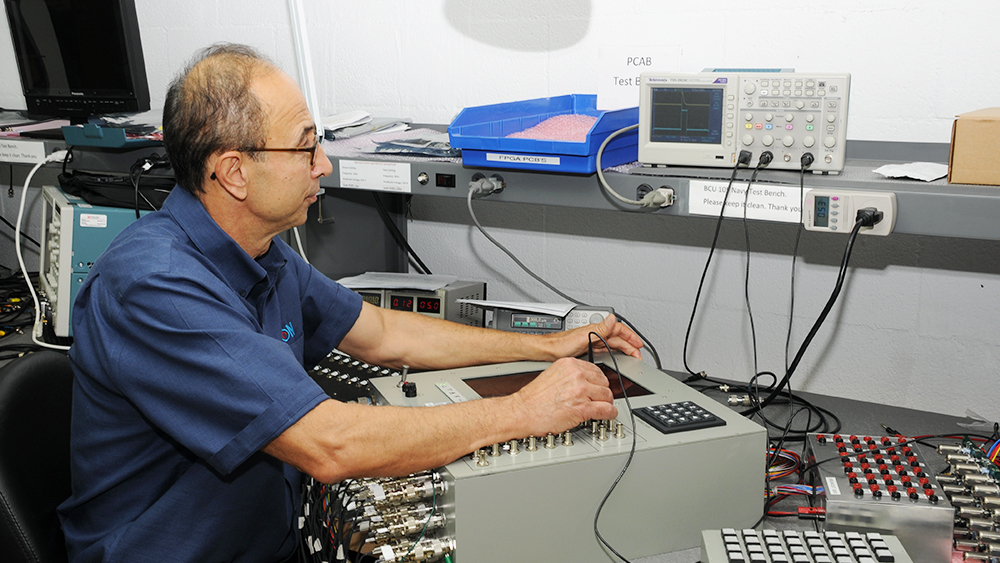

PCAB (shipborne integrated programming station/ 96 channel I/O)

Example Modification: Develop an airborne interference blanker with an increase in channels from a previous analog LRU and provide a computer controlled map generation

Eon Solution: Start with a BCU-102 (potentiometer controlled) LRU chassis. Use the FPGA board from the computer controlled PCAB and design an 18 input I/O board from the 12 input BCU-102 to create the PIBU-102 LRU. Develop a separate standalone portable field computer from the PCAB design to create the PIBU-102 PS.

Existing LRU BCU-102 (analog control/12 channels)

New PIBU-102 PS (Programming Station)

New PIBU-102 LRU (digital control/18 channels)

Hardware, Software and System Engineering Support

Eon frequently receives services contracts from customers seeking to reduce costs by outsourcing hard to do one-of-a-kind products. Eon has designed Ethernet interfaces, Torque converters, Motor controllers, Distribution panels, Video converters etc. with little or no NRE. Eon also participates in complete system design including integration of multiple LRU’s and appropriate cables to satisfy a functional requirement. Eon performs this unique work at modest prices to stay at the forefront of industry requirements. From these developments Eon can design new products for higher volume manufacturing. Eon’s 20 percent year over year growth is partially driven by this system engineering services and custom program product strategy.

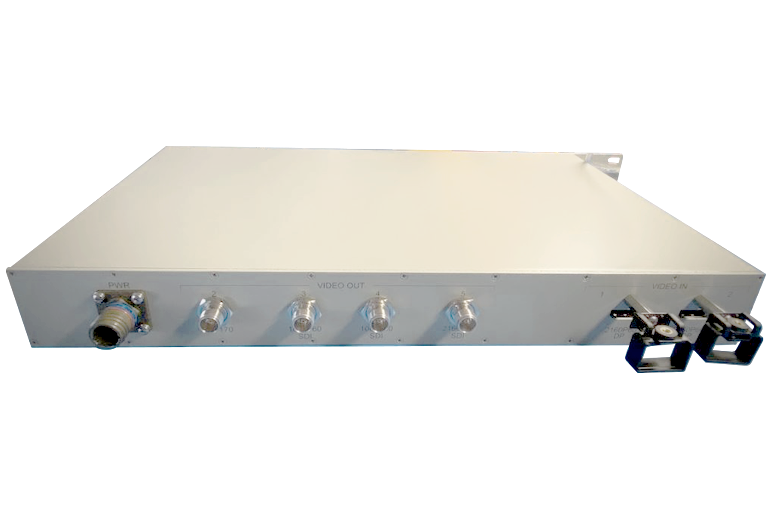

Example System Engineering Development: A complete high speed digital video processing system for a flight test application

Eon Solution: Combine Eon’s Cameras, Video Switch, Recorder, and Monitors with appropriate cabling